Ontario Farm consultant shares trellis construction guidelines.(By Ross Courtney,Good Fruit Grower article)

Put at least one quarter of a trellis post in the ground, use high-quality wire and think of tug-of-war when placing end posts.

Those are just a few tips an Ontario farm consultant shared with apple growers in January at the Empire State Producers conference in Syracuse, New York.

“If you were to canvass every apple grower you’d probably find that every grower that’s got a trellis system has five different trellis systems on their own operation,” said Hugh Fraser, proprietor of OTB Farm Solutions in St. Catharines, Ontario. “I’d be surprised, frankly, if you find two orchards with the same system anywhere because we sure don’t have any in Ontario, that’s for sure.”

That’s why Ontario Apple Growers in 2014 asked Fraser, a former engineer with the Ontario Ministry of Agriculture, to study trellises and issue a few guidelines, a tricky task from the get-go, because every farm is different. However, he said, he and the five farmers who participated came away with a few lessons they believe should be consistent.

“I’m sure no expert on trellises, but we have learned some things we think need to apply in most orchards,” he said.

Not surprisingly, as growers plant fruit trees in higher and higher densities, the demand for trellises has grown. Virtually all new orchards in Ontario have some form of trellis, Fraser said. Thus, material can be hard to find, so one of Fraser’s first tips was to plan way ahead, so trellises are in place with the trees from the beginning. Otherwise, those young trees are at risk of stress. Plan to place orders a year ahead of spring planting.

One of his most interesting tips came from the Tug of War International Federation, the tug of war equivalent of soccer’s governing body FIFA. The organization determined in a 2002 study that the participants on winning eight-person tug of war teams lean a mean of 58 degrees during their contests and that the human body will naturally, without thinking about it, adopt a 60-degree posture when asked to play tug of war.

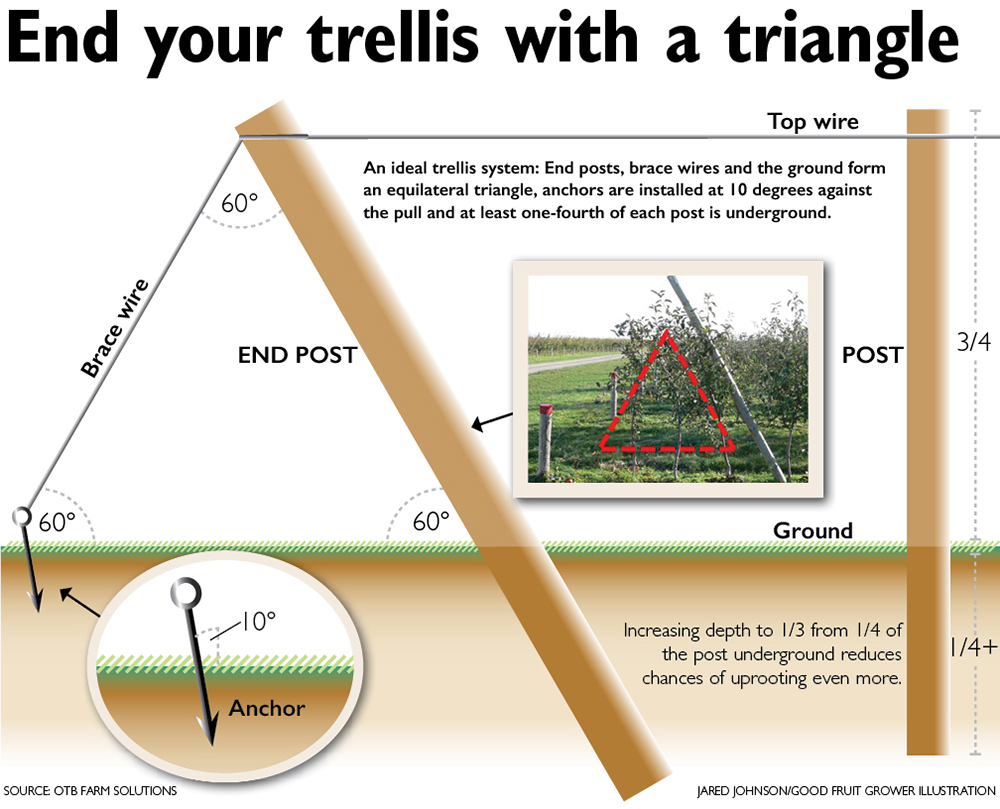

Applying that to trellises, Fraser recommends constructing end of row anchor systems so that end posts, brace wires and the ground form an equilateral triangle to equalize torque. There is wiggle room, however, he said; bumping the post up to a 70-degree angle to save space only costs minimal strength.

Here are some other tips he shared at the conference:

—Make sure at least 25 percent of trellis posts are underground. Shallow posts are a common reason for trellis failures. Increasing that to 33 percent underground reduces the chances of uprooting even more. (Another research project also found that at least one-third of the post should be underground. See “Avoiding trellis failures” on Page 10.)

—Use 12-, 14- or 16-foot posts, though they may be hard to find. Ten-foot posts don’t leave enough room for enough underground base. Even 12-foot posts barely make it.

—Posts with a 5-inch diameter are 50 percent stronger than those with only 4 inches.

—Pound or vibrate end posts into undisturbed ground instead of digging. End posts must be longer than vertical, mid-row posts, to leave enough underground, and thicker.

—Pound or vibrate anchors 4 feet into undisturbed ground, leaning 10 degrees from vertical away from the row.

—Plant a tree or two between the end post and the anchor to use space and provide a visual signal to avoid damaging the end of the wire with a tractor.

—Don’t skimp on wire or staples. Use the highest, Class 3, 12.5-gauge high tensile wire and 2-inch, double-barbed slash ended Class 3 galvanized staples.

—Place wires on windward side of in-line posts.

—Support trees by wires every 2 to 2.5 feet.

Think ahead and use your imagination. Trellises can provide a structure for netting, overhead sprinklers or orchard sensors as growers adopt new technology and techniques.

For more tips about trellis construction, request a fact sheet from the Ontario Apple Growers by emailing