By Petar Bursac, FGVL IDO

Tank mixing of pesticides or pesticides and fertilizers may save time and labour and also reduce application costs. With single application we might control a few pests and diseases and apply foliar fertilizers. It is important to pay attention to compatibility of different products before we tank mix any product. Tank mixing without checking compatibility of chemicals may cause serious problems such as loss of efficacy of some of the active ingredients, physical incompatibility between different compounds, separation, blocking of spray systems, foaming, crystallisation and most importantly phytotoxicity.

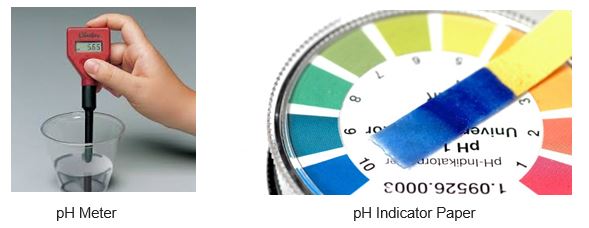

When tank mixing, we must pay attention to each of the factors which may cause incompatibility. Even if we are using a proven mix of chemicals incompatibility might occur due to water quality. Some waters may contain iron, calcium and other elements that inhibit compatibility. Some herbicides (amine salts) may react with calcium and magnesium from the water and form insoluble salts which causes decreasing pesticide efficacy. Some of the modern selective insecticides effect regulation of the concentration of calcium ions in the insect body (calcium homeostasis). Tank mix of these insecticides with calcium fertilizers may cause loss of efficacy. Stability of tank mixes depends on the water pH. Optimal water pH for pesticides should be between 6.0 and 7.0. If pH is out of this range, acidifiers and buffers should be used.

Some chemicals cannot be physically mixed together due to physical incompatibility. Physical incompatibility can be caused by improper mixing, inadequate agitation, or lack of stable emulsifiers in some ECs. These combinations of chemicals require intensive mixing and the addition of surface active ingredients (surfactants, detergents etc.) or capability agents, otherwise solids will settle out of the mixture or the mixture separate into layers. Mixing of wettable powders and emulsifiable concentrates with poor agitation can form a putty or paste with an oily layer that floats on the top of the tank. Special attention should be payed when mixing EC formulations with liquid fertilizers.

Sometimes even products that mix well should not be used together because the activity of the mixture may be different if the products were applied separately. The result can be either decreased activity, or increased activity.

New technologies introduced by foliar and liquid well balanced fertilizers, containing a full spectrum of nutrients, has been adopted by few farmers. In order to cut costs, farmers usually mix different types of fertilizers without considering the properties of mixed compounds such as purity, solubility, the incompatibility or benefits of some agents such as activators, buffers, chelates etc. Tank mixing of nitrogen fertilizers in the form of urea and ammonia may cause high pH and incompatibility with pesticides. On the other hand, phosphorus fertilizers in form of phosphate or phosphoric acid, may create tank mixes with a low pH.

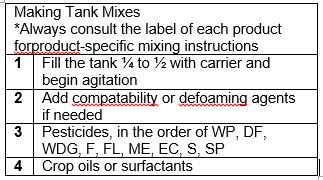

It is extremely important that we add the components of the mixture in the order that the label specifies; sometimes, whether pesticides are physically compatible or not depends on the order in which you add them to the tank. This is especially true for pesticides that are packaged in water-soluble packets; a mistake in mixing order could prevent the packet from dissolving completely, and thus prevent uniform distribution of the pesticide in the spray tank.

Many labels provide detailed methods for mixing. If labels do not make any recommendations, we must perform your own compatibility test.

There are several testing methods available and they serve different purposes and generally they are called jar tests because your initial test for compatibility should take place in a jar and not in the spray tank.

Compatibility testing

Step 1. Get a large, clean container, such as a jar. Use the same water (or other diluent) that you will use when making up the larger mixture. Add the water and each of the products in the same proportions as you will mix them. Add pesticides using the “W-A-L-E” plan:

a. Add some of the diluent first (water).

b. Add Wettable and other powders and Water-dispersible granules.

c. Agitate thoroughly and add the remaining diluent.

d. Add the Liquid products, such as solutions, surfactants, and flowables.

e. Add Emulsifiable concentrates last.

Step 2. Shake the jar vigorously. Feel the sides of the jar to determine if the mixture is giving off heat. If so, the mixture may be undergoing a chemical reaction and the pesticides should not be combined. Let the mixture stand for about 15 minutes and feel again for unusual heat.

If scum forms on the surface, if the mixture clumps, or if any solids settle to the bottom (except for wettable powders), the mixture probably is not compatible. Finally, if no signs of incompatibility appear, test the mixture on a small area of the surface where it is to be applied.

To make certain we have a uniform spray mixture at all times, it is important to keep the mixture agitated during the entire application until the tank is empty. If we do end up with a physically incompatible spray mix, the manufacturer of each product must be contacted to see if the mix can be rejuvenated. Adding a compatibility agent may return the mix to a sprayable form. If you cannot rejuvenate the mix, the mixture should be treated as pesticide waste.

Field Test of Tank Mix

After completion of the jar test and confirmation of chemical compatibility, it is important to conduct one more test in the field in order to confirm that mixture does not cause phytotoxicity or ineffectiveness. For this test, pesticide handlers need to apply the mix at the rate specified in label in a small area (a few trees, one or two bays) and observe the test plot for several days. If the mix is not harmful to treated plants and is effective on the target species, then we have a compatible mix. Prepared mix must be used in one day. Left overnight, compatible mixes may form precipitates and stratify.

General Instructions for Making Tank Mixes

Combining Pesticides with Fertilizers

Most tree plants absorb foliar applied nutrients through their leaves and to a lesser extent through shoots. The majority of plant nutrients should be applied to the ground through granular, slow release, liquid or soluble fertilizers, or a combination thereof. Foliar fertilizing should be viewed as a supplement. There are some notable exceptions, but most pesticides on the market can be safely mixed with soluble nutrients but the first step in mixing pesticides and fertilizers would be reading the pesticide label. There are few pesticide labels which specifically prohibit certain types of tank mixing, but many pesticide labels permit it, though blending pesticides with fertilizers is rarely mentioned.

There are a few pesticides for which tank mixing nutrients is sometimes not advisable. One is the fosetyl-aluminum. Fosetyl-aluminum has acidic properties which can cause problems with tank mixing metals such as micronutrients. In order to apply fosetyl-aluminum in tank mix with fertilizers a buffer needs to be added to mix but generally fosetyl-aluminum should not be applied together with micronutrients. A second product that usually does not go into tank mix with fertilizers is chlorothalonil because in some situations these mixes can cause injury. Inorganic salts of manganese should not be mixed with chlorothalonil, and none of the manganese materials should be mixed with cupric hydroxide plus sulphur as a spray-tank mixture for foliar application. None of the manganese materials and boron should be mixed with cupric hydroxide or sulphur.

Solution pH is important when adding chemicals such as insecticides and fungicides to the spray-tank-mix. For example, for iprodione (a contact fungicide), manufacturers recommend that the spray solution should be buffered to a pH of 5.0 to 7.0. The label specifies that some chemical breakdown could occur in a solution with a high pH. As additional examples, Gorsuch and Griffin (1992) report the half-life of acephate is 29, 30, 17, and 3 days at a pH of 3.0, 5.0, 7.0 and 9.0 respectively at 40° C. Malathion is stable at pH 5.0-7.0. Carbaryl has a half-life of 100-150 days at pH 6.0, 24-30 days at pH 7.0,2-3 days at pH 8.0, and24 hours at pH 9.0.

Disclaimer: The information contained in this publication is based on knowledge and understanding at the time of writing. However, while all reasonable efforts have been made to ensure that this information is correct and current, the information covered is subject to change. Fruit Growers Victoria Limited does not assume responsibility and hereby disclaims any express or implied liability whatsoever to any party for any loss or damage caused by errors or omissions, whether these errors or omissions result from negligence, accident or any other cause.

References:

- E.J. Buffington, S.K. McDonald (2006), Tank Mixing, Colorado Environmental Pesticide Education Program, Pesticide Fact Sheet #129 CEPEP 10/01

- Applying Pesticides Correctly. National Pesticide Applicator Training Core Manual. United States Department of Agriculture and Environmental Protection Agency.

- Preparing Pesticide Tank Mixes, Illinois Pesticide Applicator Training Manual 39-7, Private Applicator University of Illinois, 1999

- N. L. Powell, Spray-Tank-Mix Compatibility of Manganese, Boron and Fungicide: Solution pH and Precipitation'